At Fostet Manufacturing, one of our biggest advantages is our customized machining capabilities. We help your business solve problems, whether that means assisting to streamline your production process, or recommending the ideal metal for demanding applications. Our team has over 30 years of experience with alloy steel machining. We can help you choose the right type of alloy steel for maximum corrosion resistance, abrasion resistance, tensile strength, hardness, or machinability.

Important Types of Alloy Steel

Steel alloys combine iron and other elements to provide the ideal mechanical, chemical, and thermal properties. Chromium, molybdenum, aluminum, copper, manganese, nickel, and carbon are common in alloys.

Common alloy steel grades that we work with include:

- 4140

- 4340

- 8620

- 9130

These alloys are often used for heavy-duty parts in the automotive, industrial machinery, mining, forestry, off-shore drilling, energy, and waste management sectors.

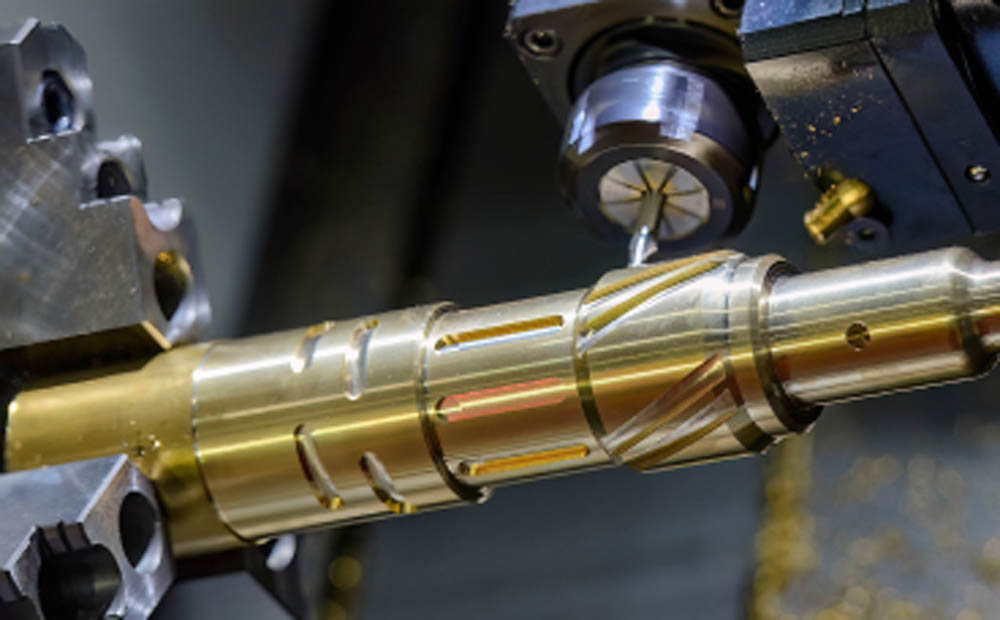

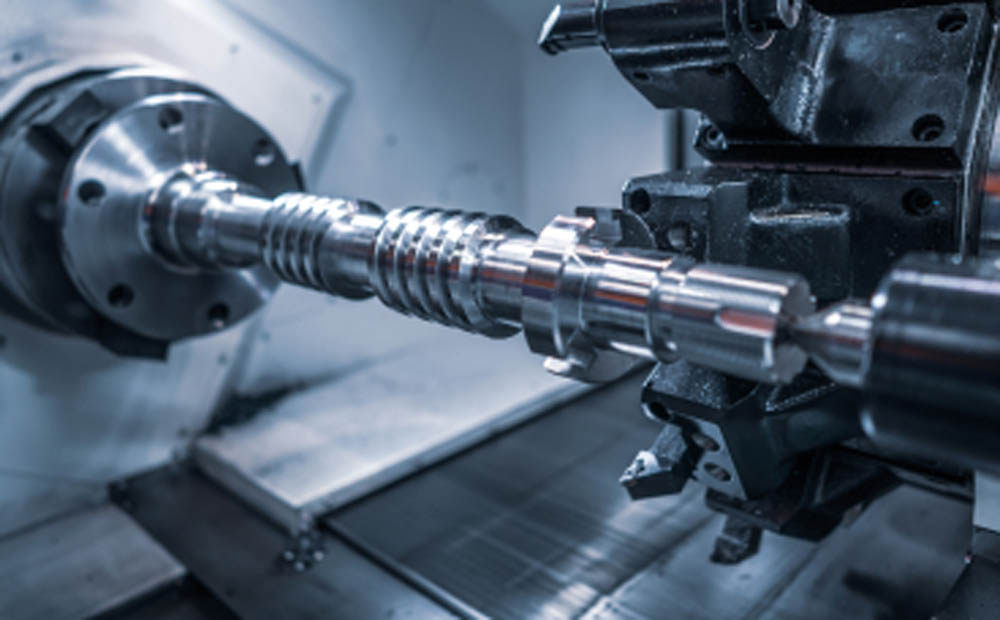

CNC Milling and Turning for Alloy Steel

Alloy steels partner well with CNC milling for precision parts. We provide a range of vertical and horizontal milling processes, including angled drilling with 4th-axis systems. CNC systems deliver outstanding speed and accuracy, letting us fulfill low and medium production volumes in just 24 to 72 hours.

Factors To Consider

Low-carbon alloys provide less corrosion resistance but greater hardness and tensile strength. Medium-alloy steels are more common for corrosive applications and exposed environments, especially in the petrochemical, oil and gas, hydroelectric, and marine industries. Different alloys offer exceptional torsion resistance, vibration resistance, load-bearing capabilities, or machinability.

A Friendly, Experienced Team

For projects using alloy steel, our team helps you consider production costs, welding requirements, part tolerances, and operating conditions. Discover the benefits of customized CNC milling and turning solutions for alloy steel. Request a quote for more information.

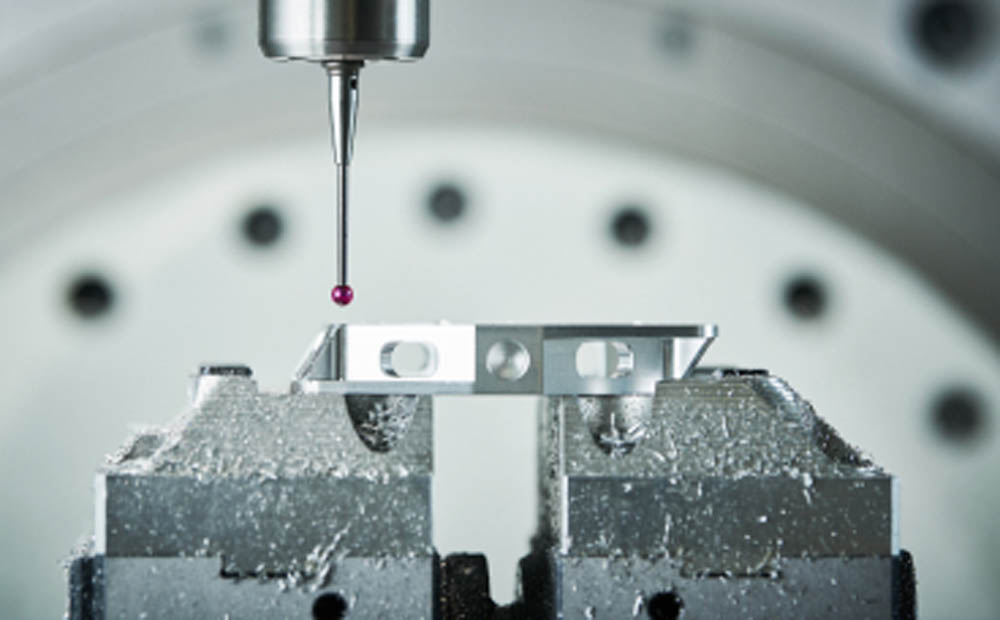

Quality Assurance and Certifications

We adhere to stringent quality standards and hold certifications such as ISO 9001, ensuring that our steel products meet the highest industry benchmarks.

Ready to Start Your Next Project? We’re Here to Help with Your Manufacturing Goals

Discover Our Versatile Capabilities

In addition to supplying high-quality alloy steel, we offer customization and processing services, including cutting, machining, and heat treating, to meet your specific requirements.