At Fostet Manufacturing Inc., we are a customer-focused company. Our main priority is to deliver high-quality products and services and provide the best customer service possible. As an ISO 9001:2015 certified company, we have strict quality and inspection guidelines for all parts we create through our CNC machining process.

Quality Control and Inspection Procedures

In our temperature-controlled quality lab, our highly skilled and trained quality control specialists thoroughly inspect parts, from the incoming material arriving at our facility, through the production process and final reviews prior to delivery to our customers. Our quality control inspection process includes the following:

- Comprehensive review of processes to ensure proper selection of inspection methods and frequencies

- Full inspection and review of incoming material to ensure certificates and conditions meet customer specifications

- First-off inspections and In Process inspections for each process: to ensure the quality of the first product is correct and carried through

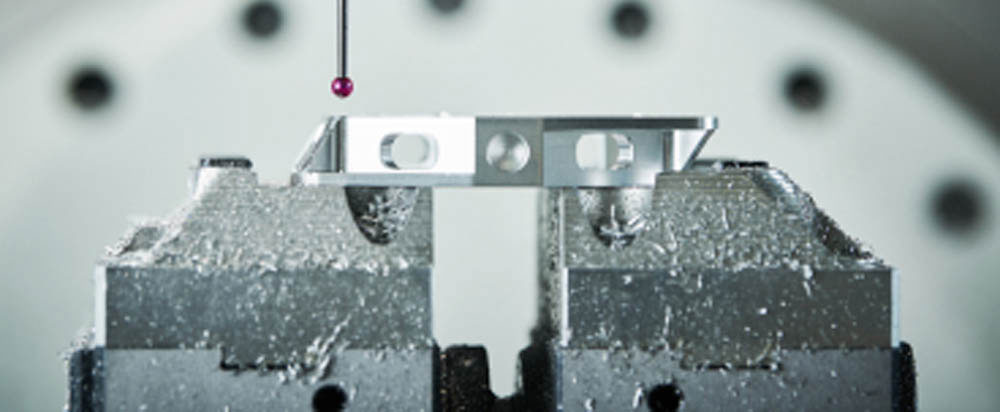

- CMM inspections and reporting: measures the dimensions and characteristics of the product to ensure product specifications.

- Preparation and submittal of customer required documentation and certificates for product delivery

Our team will continuously monitor and inspect the quality of your project to ensure it meets the industry's requirements and standards.

Equipment We Use

At Fostet Manufacturing Inc, we guarantee all projects meet our customers specifications. The equipment we use for quality control inspections includes:

- Wenzel CMM Model: XO-107 with Renishaw PH-20 Head Probing

- Mitutoyo PH3500 Optical Profile Projector with 14” screen

- Mitutoyo Laser Scan Micrometer

- Mitutoyo Contour Tracer

- Rockwell Hardness Tester - Model HR150A

- Asimeto Portable Hardness Testers

- Extensive selection of imperial and metric measuring instruments

Comprehensive Quality Inspections for CNC Machined Parts

At Fostet Manufacturing Inc , quality is not just a standard but a requirement. With our rigorous quality control and inspection requirements in place, you can rest assured that your parts will meet your industry's most stringent standards. We can provide you with the inspection reports and certificates for the material and parts as required. If you have questions or want to discuss your project with a member of our staff, contact us today to request a quote.

Quality Assurance and Certifications

We adhere to stringent quality standards and hold certifications such as ISO 9001, ensuring that our steel products meet the highest industry benchmarks.